Tuesday, December 14, 2010

Log 12/14/2010

Today I am finishing up my more detailed 3D CAD drawing and working on my press release, which is due December 21st.

Thursday, December 9, 2010

Log 12/9/2010

I have finished my amended 3D CAD drawing and I'm not really sure of where to go from here, so now I am working on making my drawing more detailed. Right now I've hit a road block while drawing a detailed version of my camera because the dimensions given on the website where I purchased the camera do not seem to match up with the picture of the camera (one side seems entirely too long). Now I am just waiting for my camera to arrive, which should be any day now, so that I can finish my drawing.

Tuesday, December 7, 2010

Amended Orthographic AutoCAD Drawings

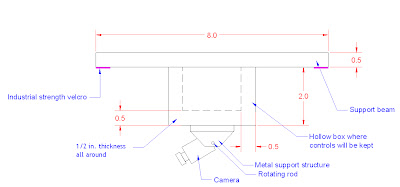

*all measurements are in inches

These are the amended orthographic drawings of my project. Please note the change in dimensions of the support beam and control housing box. I also showed that the box is hollow. I also added industrial strength Velcro to the underside of the support beams. My partner, ES, and I came up with this solution after our instructor, DA, suggested that we make my piece removable from the vessel. The edges of the vessel will have industrial strength Velcro so that the two separate pieces will attach and unattach easily.

All drawings done by MM using AutoCAD.

These are the amended orthographic drawings of my project. Please note the change in dimensions of the support beam and control housing box. I also showed that the box is hollow. I also added industrial strength Velcro to the underside of the support beams. My partner, ES, and I came up with this solution after our instructor, DA, suggested that we make my piece removable from the vessel. The edges of the vessel will have industrial strength Velcro so that the two separate pieces will attach and unattach easily.

|

| Fig. 1: Top View |

|

| Fig. 2: Bottom view |

|

| Fig. 3: Front View |

|

| Fig. 4: Side view |

All drawings done by MM using AutoCAD.

Log 12/7/2010

My partner, ES, and I decided to use plastic industrial strength Velcro to attach our two parts together. The Velcro is strong enough to keep my design attached to the rest of the vessel, but if for whatever reason we need to fix any part of my design we can detach the two parts.

Today I finished my amended orthographic CAD drawings. These include dimension adjustments and the addition of Velcro.

Sources:

Figure 1: http://www.canadiandriver.com/forum/index.php?topic=62241.0

| |||||

| Fig. 1: Plastic industrial strength Velcro made by 3M |

Sources:

Figure 1: http://www.canadiandriver.com/forum/index.php?topic=62241.0

Friday, December 3, 2010

Log 12/3/2010

Last night I ordered the camera, which should arrive in 3-5 business days. I took apart the RC car last night as well. I have pictures that I will upload once I have labels on the pictures explaining what it showing.

Today in class I updated my 3D AutoCAD drawing so that the box holding the electronics was bigger and hollow and the support beams were made longer so that they can fit with the new, larger dimensions of the vessel. I have to add more lights and adjust the materials rendered onto the drawing before I can post it.

Also today, with the help of my classmates, I tested the range of the RC car, which will tell me how far out we can send the vessel. Unfortunately, the RC car only made it about 150 feet and only went another 20 feet when we held the radio control up above our heads. Even with the extra 20 feet, the range of the RC car was 280 feet less than the range of the camera. This means the farthest the vessel can go is about 150 feet because any farther than that we will lose control of it. I had my classmates TH, SW, and CM control the RC car to prove that my camera controller will be easy to operate without extensive training, which makes it very user-friendly.

Today in class I updated my 3D AutoCAD drawing so that the box holding the electronics was bigger and hollow and the support beams were made longer so that they can fit with the new, larger dimensions of the vessel. I have to add more lights and adjust the materials rendered onto the drawing before I can post it.

Also today, with the help of my classmates, I tested the range of the RC car, which will tell me how far out we can send the vessel. Unfortunately, the RC car only made it about 150 feet and only went another 20 feet when we held the radio control up above our heads. Even with the extra 20 feet, the range of the RC car was 280 feet less than the range of the camera. This means the farthest the vessel can go is about 150 feet because any farther than that we will lose control of it. I had my classmates TH, SW, and CM control the RC car to prove that my camera controller will be easy to operate without extensive training, which makes it very user-friendly.

Wednesday, December 1, 2010

Log 12/1/2010

I have to go through my blog and change any place it says that I will be using a servo because the RC car I will be taking parts from operates both systems on motors. I will make corrections accordingly.

Labels:

Logs

Subscribe to:

Comments (Atom)